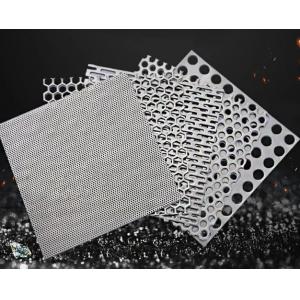

Perforated metal mesh is made by punching metal plate with a certain shape by machine.

Advantages of perforated mesh:

- Ease of shaping: Perforated mesh can be easily shaped and can also be painted or polished according to requirements.

- Ease of installation: Installing perforated mesh is a hassle-free process.

- Attractive appearance: The mesh boasts an appealing visual appeal.

- Versatile thicknesses: Various thicknesses of sheet metal are available for different needs.

- Diverse apertures and arrangements: The mesh is offered in a variety of aperture sizes and arrangements.

- Good sound absorption: Perforated mesh exhibits excellent sound absorption properties.

- Lightweight: The mesh is lightweight, making it convenient to work with.

- Long service life: The mesh has a prolonged lifespan.

- Precise sizing: The mesh is manufactured with precise dimensions.

- Extraordinary wear resistance: The mesh demonstrates exceptional resistance to wear and tear.

Uses: Perforated mesh finds wide applications, including but not limited to:

- Protective covers for mechanical equipment.

- Air filtration and sound insulation boards for environmental noise control.

- Ceiling decorations.

- Mesh covers for high-quality speakers.

- Sieves for grain, feed, dust mills, and mines.

- I-shaped sieves.

- Stainless steel fruit baskets for the kitchen.

- Food covers.

- Oil fishing nets.

- Fruit plates and other kitchen utensils.

- Shelf netting for shopping malls.

- Ventilation and ventilation nets for granaries.

- Water seepage filter screens for football field lawns.

- Various decorative exhibition stands.

- Environmental-friendly trash cans.

- Environmentally-friendly tables and chairs, etc.

Application: